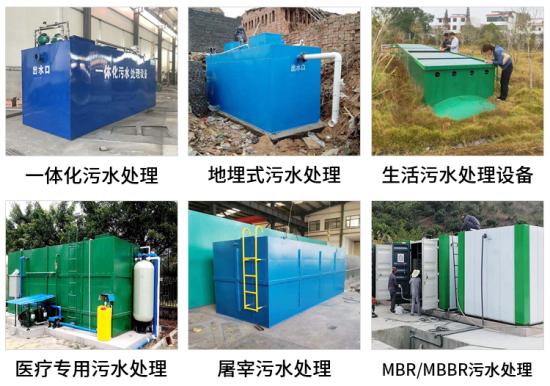

- 环保局又来查!智能一体化污水设备7天达标排放方案

《环保局又来查!智能一体化污水设备7天达标排放方案》最近不少企业老板都在吐槽:"环保局巡查越来越频繁,污水处理整改压力山大,厂里旧设备根本扛不住新标准!"根据生态环境部2024年数据,全国工业污水排放超标企业中有72%因处理设施落后被处罚。面对动辄数十万的罚款和停产风险,一套能快速落地的解决方案正在成为刚需。传统工艺的...

2025-05-01

- 污水处理厂入河排污口论证报告怎么写

《入河排污口监督管理办法》明确规定:设置入河排污口的单位,应当在向环境保护行政主管部门报送建设项目环境影响报告书(表)之前,向有管辖权的县级以上地方人民政府水行政主管部门或者流域管理机构提出入河排污口设置申请。总结来说污水处理厂入河排污口设置审批是项目环评审批、排污许可证发放的前置条件。污水处理厂入河排污口论证报告即是...

2025-02-07

- 污水处理方案怎么写

污水处理方案的编写,有着一套完整的流程,针对各个不同废水类型,其工艺要点也不尽相同,接下来,小编将以一个通俗污水处理方案的编写流程为大家展示污水处理方案到底该怎么写。效益分析污水处理的处理费用分析计算,维护成本计算,所产生的效益分析计算等。

2025-02-07

- 构建智能生活,纯水机控制板线路图解密

作为现代生活中的必备品之一,纯水机在我们的日常生活中扮演着至关重要的角色。它通过高效的过滤系统,将自来水中的杂质和有害物质去除,为我们提供了清洁、安全的饮用水源。而控制板作为纯水机的核心控制部件,其设计与功能直接影响着纯水机的性能和稳定性。 让我们来看一下纯水机控制板线路图的基本构造。控制板通常由主芯片、...

2024-05-04

- 极致纯净,畅饮人间瑶池——纯水设备机械设备全解析

当今社会,健康成为人们越来越关注的焦点。而饮水安全作为健康的基石,更是备受重视。在纯净水领域,纯水设备机械设备扮演着至关重要的角色,其作用不可小觑。纯水设备机械设备究竟包括哪些设备呢?让我们一探究竟。 我们要了解的是反渗透设备。反渗透设备,简称RO设备,是纯水设备机械设备中的核心组成部分之一。其原理是利用...

2024-05-04

- 极简生活,从纯水机开始

随着人们生活水平的提高,对生活品质的追求也日益增加。在这个追求健康、舒适的时代,纯水机作为净水设备的一种,越来越受到人们的关注和青睐。它不仅能够去除水中的杂质、异味,更重要的是能够提供给我们清洁、健康的饮用水,保障家人的健康。 纯水机是什么? 纯水机,顾名思义,就是一种可以产生纯净水的设备。...

2024-05-04

- 揭秘纯净水机的制水原理

纯净水的价值 纯净水,作为人们日常生活中不可或缺的饮用水资源,其质量直接关系到人们的健康和生活质量。在如今水污染日益严重的环境下,纯净水机成为了人们获得高质量饮用水的主要途径之一。纯净水机究竟是如何实现制水的呢? 我们需要了解纯净水机的基本组成。一般而言,纯净水机由进水系统、预处理系统、膜分...

2024-05-03

- 揭秘水厂纯净水设备,打造健康生活的清流

part1:纯净水设备的种类及工作原理 现代社会注重健康生活,纯净水成为家庭生活中不可或缺的一部分。水厂纯净水设备通过一系列工艺和技术,将自来水中的杂质和有害物质过滤除去,提供给人们清澈透明、无异味的饮用水。下面我们将逐一介绍几种常见的纯净水设备及其工作原理。 第一种是反渗透纯净水设备。反渗...

2024-05-03

- 揭秘水厂纯净水设备操作工的日常工作:从辛苦到满足的转变

当我们打开水龙头,享受清澈见底的水质时,很少有人会想到这清澈水源背后隐藏的辛劳。而在水厂,有一群默默无闻的纯净水设备操作工,他们的工作,正是保障了我们日常饮水的安全和质量。水厂纯净水设备操作工的工作到底是怎样的呢?这其中的辛劳和付出又有多少人了解呢? 作为水厂中不可或缺的一环,纯净水设备操作工需要具备丰富...

2024-05-03

- 探秘纯水设备工作流程:解密纯水的制备过程

纯水是一种应用广泛的水质标准,它在许多领域都有着重要的用途,如制药、电子、化工、食品等。而要生产出高纯度的纯水,离不开先进的纯水设备和精密的工艺流程。下面,让我们一起探秘纯水设备的工作流程,了解纯水从原水到纯净水的制备过程。 纯水设备的工作流程始于原水的处理。原水可以是自来水、井水或河水等,但这些水源中通...

2024-05-02

- 探秘纯水机的神奇原理:让生活水源变清澈明净

生活中,水是我们不可或缺的生命之源,而纯净的水更是我们身体健康的保障。由于环境污染和水源污染的加剧,自来水质量参差不齐,难以直接饮用。这时,纯水机作为一种常见的水处理设备应运而生。它不仅能够去除自来水中的异味和余氯,更能有效清除其中的重金属、细菌、病毒等有害物质,提供给我们清澈、健康的饮用水。 纯水机的工...

2024-05-01

- 探秘纯水机的工作原理合集

作为现代家庭不可或缺的一部分,纯水机的工作原理深受人们关注。纯水机的工作原理主要通过一系列过滤技术来实现水质的净化,确保饮用水的纯净和健康。纯水机利用多层过滤器进行初步的水质过滤。这些过滤器通常包括预过滤器、活性炭过滤器和颗粒碳过滤器。预过滤器能够去除水中的大颗粒杂质,如泥沙、锈迹等;活性炭过滤器则能有效吸附水中的异味...

2024-05-01